Strength

Overview

Industry standards provide a basis for comparing the relative performance of competing products. There is an accepted standard for testing the strength of ceiling products, so one might expect test results to be disclosed by ceiling manufacturers. Yet manufacturers of mineral fiber ceiling panels seldom reveal the strength of their products. The reason for their silence is that mineral fiber panels do not have much strength.

People that install or handle mineral fiber ceiling panels already know this: panels can break even before they are removed from shipping cartons, while being manipulated to fit into a ceiling suspension grid, and when panels are lifted to perform above-ceiling maintenance. Even when handled with care, wear on edges and corners of panels will release fibers into the air.

Ceilume ceiling panels and tiles, on the other hand, are surprisingly strong. They flex to make it easy to install panels in tight locations. They are lightweight and robust, and do not break if dropped or handled roughly.

To better understand the strength of our ceiling tiles, we have tested our products in accordance with the standard, ASTM C367 - Strength Properties of Prefabricated Architectural Acoustical Tile or Lay-in Ceiling Panels. As a basis for comparison, we also tested a popular mineral fiber panel from a leading manufacturer. Tests were performed by an independent laboratory.

Results

Ceilume ceiling panels outperform mineral fiber panels. In fact, Ceilume's test results are an order of magnitude better than those of mineral fiber products in all four tests prescribed by the standard.

| Property | Average | |

|---|---|---|

| Hardness, lbf | ||

| Ceilume | 8823 | |

| Mineral Fiber | 132 | |

| Friability, % mass loss | 10 minutes | 20 minutes |

| Ceilume | 0 | 0 |

| Mineral Fiber | 8.7 | 13.5 |

| Sag, inch | Permanent Sag (Recovery) | |

| Ceilume | 0.096 | |

| Mineral Fiber | 0.764 | |

| Transverse Strength (Flexure) | Break Load, lbf | Modulus of Rupture, psi |

| Ceilume | Didn't Break | At yield, 1298 |

| Mineral Fiber | 5.6 | 78 |

The Four Tests

Hardness: The force required to press a steel sphere into a panel has a direct correlation to hardness and usually indicates impact and abuse resistance. Thermoformed panels resisted 66 times more force than mineral fiber.

Friability: Specimens are placed in a rotating tumbler, then taken out and weighed at prescribed intervals. Specimens that lose the most mass are more friable and prone to damage, especially at corners and edges. Mineral fiber samples lost over 13% of their total mass in twenty minutes. Thermoformed panels lost nothing. Friability is especially a concern with mineral fiber materials because airborne fibers, including silica fibers, can cause respiratory and other health problems.

Center: Mineral fiber ceiling panels after testing.

Right: Ceilume ceiling panels after testing.

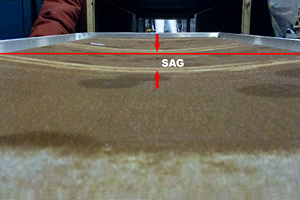

Sag: Panels are exposed to elevated temperature and humidity, then returned to ambient room conditions and measured for sag. Thermoformed panels exhibited less than 1/10-inch of sag. Mineral fiber had more than 3/4-inch of sag because they have a propensity to weaken as they absorb moisture. A 3/4-inch sag will be clearly visible at normal suspended ceiling heights.

Transverse Strength: Panels are tested in a hydraulic testing machine and the load is recorded at which panels break or are unable to resist more load. The greater the modulus of rupture (flexural strength), the less likely a panel is to be damaged in the field. Mineral fiber broke at a load of 5.6 lbf. Thermoformed vinyl did not break, and had a modulus of rupture 16 times greater than mineral fiber.

Further Considerations

The test data supports findings that mineral fiber panels are relatively fragile, prone to damage when handled, and sag when exposed to humidity and moisture.

The laboratory testing confirms field observations that Ceilume panels are durable enough to install without damage, retain their appearance despite repeated handling for maintenance, and withstand the types of abuse expected in most buildings.

In addition to outperforming mineral fiber panels for strength, Ceilume panels also exceeded the performance of mineral fiber ceilings when tested for stain resistance and washability.

Ceilume panels are only 20 percent of the weight of mineral fiber products. This means their strength-to-weight ratio, a measure of engineering performance, is all the more impressive. Reducing the use of raw materials contributes to the sustainability of Ceilume panels.

More Information

- Contact Ceilume for free sample panels and conduct your own strength tests.

- See "A Rational Approach to Ceiling Product Evaluation," The Construction Specifier and "Testing the Strength of Ceilings", Interior Construction.

- Contact a mineral fiber manufacturer and ask for ASTM C367 test results for their products; that will be fun.