Hygiene

In addition to being an attractive solution for many construction related issues, Ceilume's ceiling tiles and panels can be used in facilities with rigorous criteria for cleanliness and environmental hygiene. They:

- Are washable and easy to clean

- Promote healthy indoor air quality, dampen acoustics, and contribute to other environmental benefits

- Can be installed beneath fire sprinklers and lighting to protect occupied spaces against the contaminants that collect on exposed pipes and fixtures

CDC Disinfection Guidelines

Ceilings are thought to be less involved in the transmission of COVID-19 than are surfaces that can be touched. The following guidelines, however, pertain to most interior building surfaces (quotes from CDC website, "When and How to Clean and Disinfect a Facility", updated November 2, 2022):

- "Clean the surface with soap and water first."

- "To disinfect, use an EPA-registered disinfecting product for the specific harmful germ..."

Comment: Ceilume products are impervious to water and are not harmed by regular cleaning with ordinary household and janitorial soaps, detergents, and non-abrasive cleansers.

Comment: Ceilume panels and tiles have been tested for resistance to alcohol, hydrogen peroxide, bleach, povidone iodine, chlorine compounds, and other chemicals. Click here to see test data on stain resistance. For resistance to other reagents, contact us for free samples you can use to test proposed disinfectants and application techniques. Our products are made with high-quality rigid vinyl, a material with excellent resistance to damage by many types of chemicals.

Note: Ceilume products have not been tested with Germicidal Ultraviolet (GUV) or Ultraviolet Germicidal Irradiation (UVGI); contact us before use.

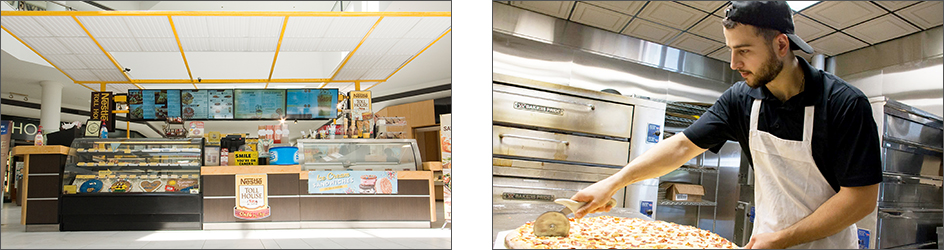

Food-Processing and Preparation Areas

Ceilume ceiling panels and tiles comply with the requirements of the Food and Drug Administration (FDA), United States Department of Agriculture (USDA), and state and local health departments for installation over food-processing and food-preparation areas.

These authorities mandate that food-handling areas must be protected against broken glass and contaminants that accumulate on exposed pipes and light fixtures. The easiest way to meet these requirements is to install light fixtures and fire sprinklers above light-transmitting, drop-out ceiling tiles.

When a project needs approval by a health inspector, we suggest showing the proposed ceiling panels before placing a full order. Please do not hesitate to contact us for free samples and the answers to any questions you may have.

FDA Food Code

6-101.11 Surface Characteristics

-

...ceiling surfaces under conditions of normal use shall be:

- Smooth, durable, and easily cleanable for areas where food establishment operations are conducted;

- Nonabsorbent for areas subject to moisture such as food preparation areas, walk-in refrigerators, warewashing areas, toilet rooms, mobile food establishment servicing areas, and areas subject to flushing or spray cleaning methods.

6-201.11 Floors, Walls, and Ceilings

- ...ceilings shall be designed, constructed, and installed so they are smooth and easily cleanable.

6-201.12 Floors, Walls, and Ceilings, Utility Lines

- Utility service lines and pipes may not be unnecessarily exposed.

- Exposed utility service lines and pipes shall be installed so they do not obstruct or prevent cleaning of floors, walls, or ceilings.

USDA Code of Federal Regulations: Title 21 - Food and Drugs

§ 110.20 Plant and Grounds

-

...buildings and structures shall... facilitate maintenance and sanitary operations for food-manufacturing purposes. The plant and facilities shall:

- Be constructed in such a manner that... ceilings may be adequately cleaned and kept clean and kept in good repair; that drip or condensate from fixtures, ducts and pipes does not contaminate food, food-contact surfaces, or food-packaging materials...

- ...provide safety-type light bulbs, fixtures, skylights, or other glass suspended over exposed food in any step of preparation or otherwise protect against food contamination in case of glass breakage.

Pharmaceutical Areas

Ceiling tiles and panels also comply with standards set by the U.S. Pharmacopeial Convention (USP) for construction and preparation areas for drug manufacturing. The USP is an annually published compendium dictating standards for medicines, food ingredients, dietary supplement products, and ingredients.

USP General Chapter <797> Pharmaceutical Compounding - Sterile Preparations

4.3 Constructing Areas to Achieve Easily Cleanable Conditions

-

The surfaces of ceilings... in a classified area or in a segregated compounding area must be smooth, impervious, free from cracks and crevices, and non-shedding, thereby promoting cleanability

and minimizing spaces in which microorganisms and other contaminants can accumulate. Surfaces must be resistant to damage by disinfectants... If ceilings consist of inlaid panels, the panels

must be impregnated with a polymer to render them impervious and hydrophobic, and they must be sealed. Classified areas and segregated compounding areas must not contain dust-collecting

overhangs, such as utility pipes.

6.3 Cleaning and Disinfecting Floors, Ceilings, Walls, and Shelving

-

...In all ISO-classified and segregated compounding areas, the... ceilings... must be cleaned and disinfected monthly.

Other Critical Facilities

Use Ceilume ceiling panels and tiles in lab, healthcare, veterinary, pharmaceutical, and industrial environments to meet both the designer's interest in aesthetically pleasing solutions and hygiene requirements.